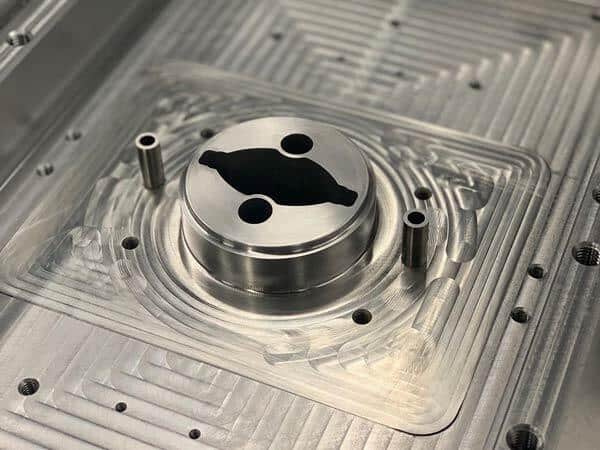

CNC Machined Materials

At DDPROTOTYPE, we use advanced equipment to provide you with various CNC machining services, including milling, turning, EDM, WEDM, surface finishing, etc. With our imported 3 axis, 4 axis, and 5 axis CNC machining centers, our skilled machinists can use a variety of plastic and metal materials to make turning and milling parts.