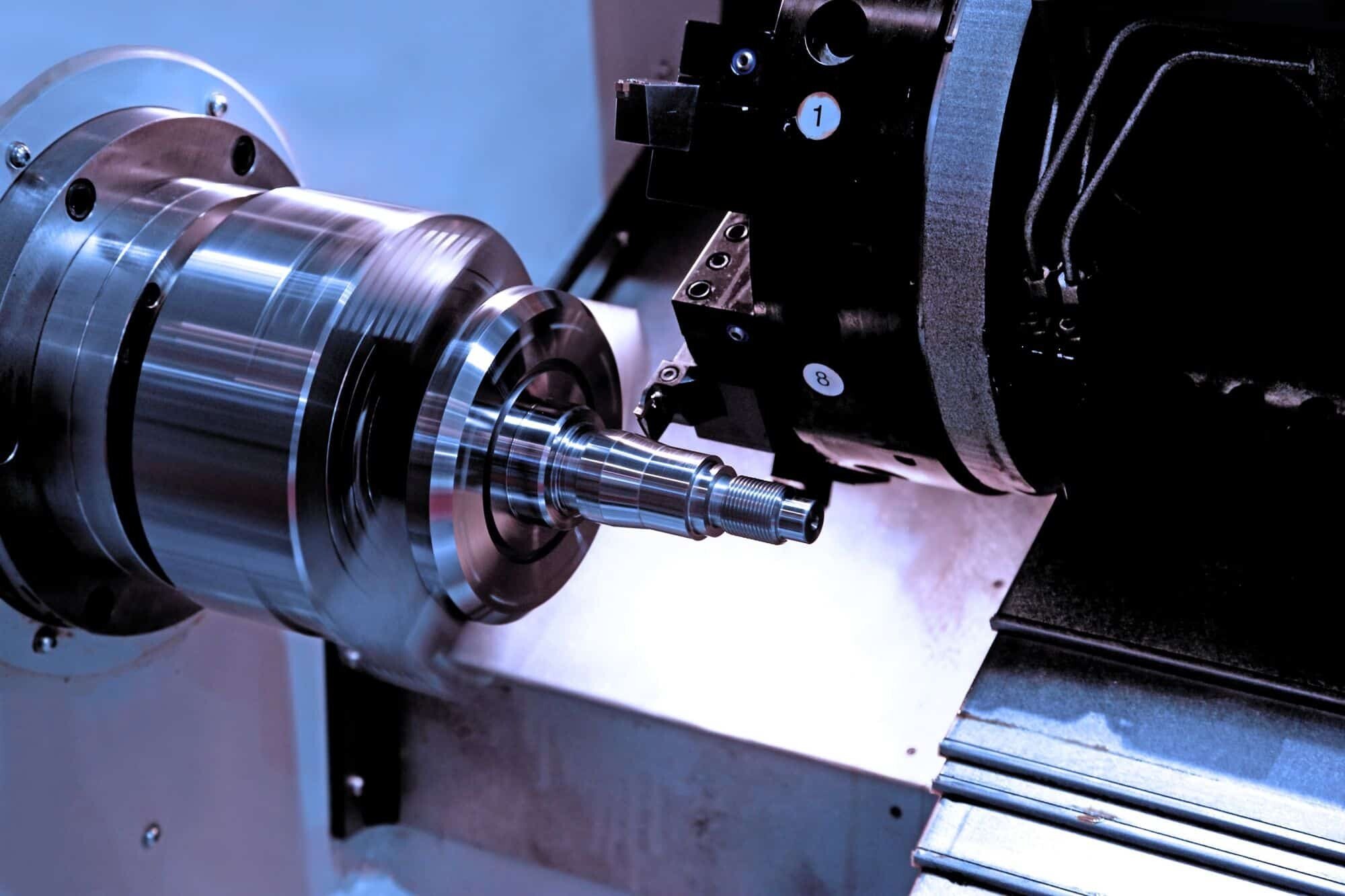

The first type of processing route is from rough turning to semi-finishing turning and then finish turning, which is the mainly processing route option for the outer circle processing of shaft parts with common materials.

The second type of processing route is from rough turning to semi-finishing turning, then to rough grinding and finally takes fine grinding. For ferrous metal materials (such as mold steel, alloy steel, or hardened materials after heat treatment, etc.), and the part need to do quenching treatment with highly requirements of accuracy and surface roughness, such processing route will be the best option, as grinding processing is ideal choice for the strict requirements of surface roughness.

The third type of processing route is from rough turning to semi-finishing turning, then to finish turning and diamond turning. Such kind of processing route is dedicated to use for machining non-ferrous metal material (aluminum, brass, etc), as the hardness is low for non-ferrous metal material and easy to block the gaps between sand grains. Usually using grinding processing can’t meet the requirement of the surface roughness and have to take finish turning and diamond turning.

The last type of processing route is from rough turning to semi-finish turning, then rough grinding, fine grinding, and finally polishing processing. Such processing route usually applied for the ferrous metal materials after quenching treatment, and the parts also with highly requirements of accuracy and surface roughness.