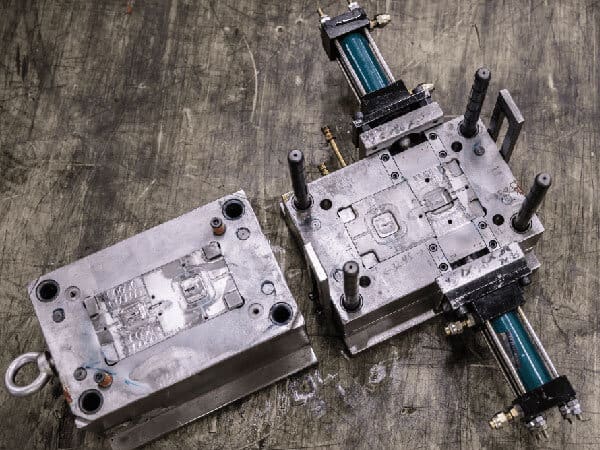

Rapid Tooling Case

DDPROTOTYPE provides aluminum mold and steel mold for rapid tooling according to the needs of customers. It can hand over the parts of your designated materials within 2-5 weeks. we combine rapid injection molding advanced equipment with proprietary technology and experienced manufacturing teams to help you reduce design risk and save overall production cost.