Rapid Prototyping & Rapid Manufacturing Expert

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion

CNC Machined Materials

DDPROTOTYPE is pleased to introduce six CNC machined materials: four metals and two plastics. In addition to aluminum, there are three kinds of stainless steel alloys, acrylic, HDPE, 7075 aluminum, brass, 17-4 PH stainless steel, 1018 low carbon steel.

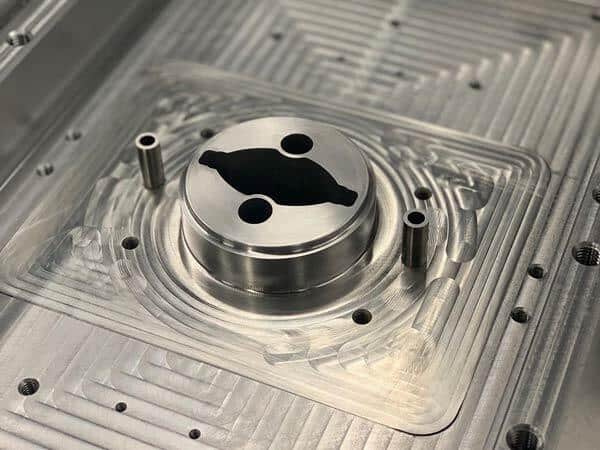

At DDPROTOTYPE, we use advanced equipment to provide you with various CNC machining services, including milling, turning, EDM, WEDM, surface finishing, etc. With our imported 3 axis, 4 axis, and 5 axis CNC machining centers, our skilled machinists can use a variety of plastic and metal materials to make turning and milling parts. Our CNC machining capability also complements our 3D metal printing service, making us an excellent one-stop service for your advanced design.

1. acrylic

Overview: scratch resistant plastic material.

Common applications: tanks, panels and optical applications.

Color: optically transparent, opaque

Appearance: transparent or opaque when not finished. After processing, transparent acrylic will present a frosted, translucent appearance, although it can be smoothed to an optically transparent state again using various finishing methods.

Design note: it may be a little brittle in thin-walled areas, so it is not recommended for delicate or complex geometry.

2. High density polyethylene

HDPE CNC processing materials

Overview: plastic material is excellent electrical insulator, and has moisture-proof and chemical corrosion resistance.

Common applications: often machined into plugs and seals

Color: white

Appearance: due to its crystal structure, HDPE is naturally opaque white, but it can also be dyed black, and the inventory is limited. It has a wax coating and is very suitable for low friction applications.

3.7075 aluminum

7075 aluminum alloy CNC machining materials

Overview: hard, high strength alternative 6061 aluminum.

It is also corrosion-resistant, non-magnetic and heat treatable.

Finish: untreated aluminum usually has a dull silver / grey finish, depending on the surface roughness. Aluminum can be anodized, sandblasted and hand polished to achieve a variety of surface finishes.

4.360 brass

Brass CNC material

Overview: due to the highest lead content in brass alloy, it is also called free machining brass. This material has excellent machinability, which means minimal tool wear.

Common applications: gear, lock components, pipe fittings and decorative applications

Surface treatment: the glossy yellow surface changes according to the surface roughness. It can be hand polished to add luster (think small or saxophone), or sandblasted to get more matte texture.

5. 17-4 PH stainless steel

17-4 PH stainless steel CNC processing material

Overview: materials with high strength and high corrosion resistance can keep their durability below 1100 ° F. The name pH stands for precipitation hardening, which is treated to improve yield strength. It can be magnetic and heat treated, and its hardness is about Rockwell C50.

Surface treatment: the surface treatment of stainless steel varies greatly according to the surface roughness, but it is usually characterized by its luster, darker color and more silver than the unfinished aluminum alloy.

Stainless steel can be powder coated, electroplated, polished or sandblasted to achieve a variety of surface effects.

6. 1018 low carbon steel

1018 low carbon steel numerical control processing material

Overview: cost effective and highly Machinable, weldable and useful without the need for high strength.

Common applications: clamps and mounting plates

Surface treatment: the surface treatment of 1018 steel is similar to that of stainless steel: the surface is usually glossy, slightly darker than that of aluminum alloy. Stainless steel can also be medium sandblasted, hand polished and powder coated to achieve a variety of surface treatments.

3 -axis, 4 -axis, and 5-axis CNC machining services, including milling, turning, EDM, and wire cutting EDM. Suitable for aluminum, steel, stainless steel, magnesium, titanium, zinc, brass, bronze, copper, ABS, Polycarbonate, Polypropylene, Polystyrene, POM, PMMA, PAGF30, PCGF30, PTFE, DHPE, HDPE, PPS and Peek.

DDPROTOTYPE provides CNC turning functions, such as end face, thread, drilling, boring, reaming and taper turning. Capable of machining CNC milled parts with a tolerance of + / -0.005 mm. Prototype and production run. Suitable for functional prototypes, gaskets, manifolds, accessories, shafts, bushings and circuit boards. Serve the automotive, aerospace, medical and consumer electronics industries. On time delivery.