5 Tips for Quality Control for CNC Machining Process and Products

DDPROTOTYPE is focusing on CNC machined parts quality control for each task, confirming each customer gets the desired item.

Discover the industry background

Based upon the various requirements in various sectors, when we acquired an order, apart from concentrating on design illustrations, we also require to comprehend the market background. As an example, also military and scientific elements normally require to come in outstanding precision, straight-out security, remarkably high quality, and likewise tight resistance, potentially require to hold up against serious conditions. DEK focuses on tailor-made CNC machined parts in a vast array of vital markets, like medical, food handling and packaging, electronic gadgets, automobile, aerospace, military, marine, equipment gadget, advanced, and likewise a lot more.

Comprehend the design of the product

When clients send a CAD drawing of the end product, our designers and engineers will examine the style in detail in addition to very carefully, understand the product specifications and requirements of clients, have a look at each info prior to production. We’ll use one of the most cost-effective option to machine your component, handle the components throughout the CNC machining procedure, and guarantee achieve the needs.

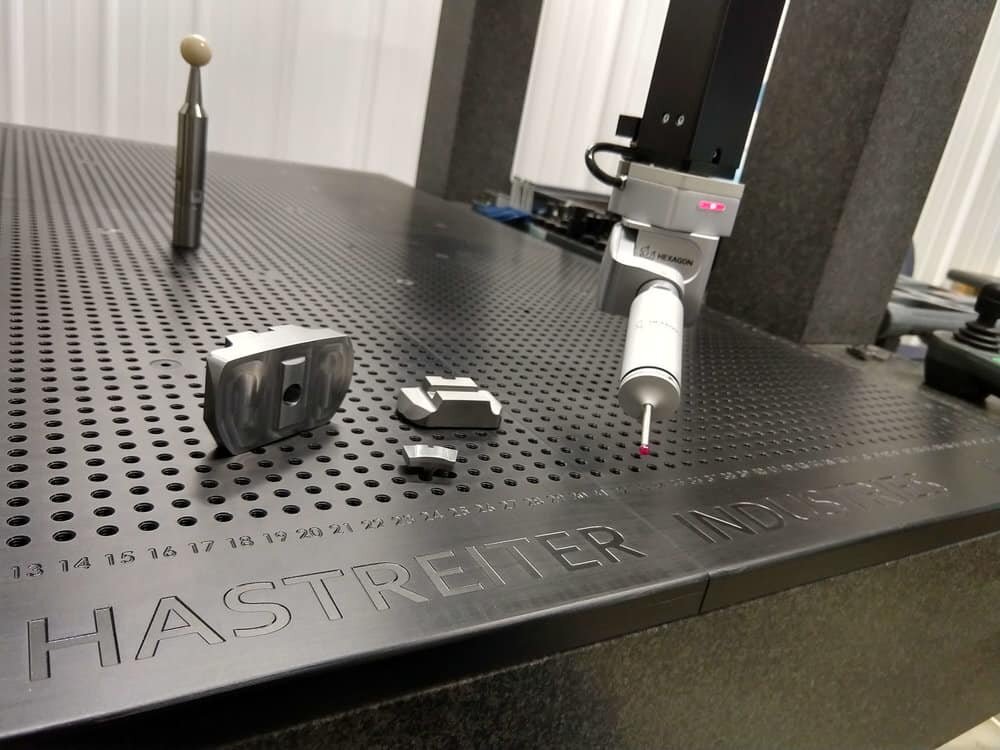

Take a look at parts with precise identifying device

Professional measuring equipment operators at DEK will certainly work with the final elements after machining. Assessors might do evaluations on the element either it’s on the maker or after removing it from the maker.

When the component is running, do evaluation

Occasionally, we need to perform a high quality evaluation when the machined component is running, so regarding identify difficulties early and likewise revamp the part prior to finishing. There are some operations that can be done to readjust the device for holding tighter resistance, such as changing the tool offsets to leave a little excess stock, permit the gadget to machine the work surface, assess what the tool has in fact done, and also more. This is particularly ideal for freshly developed products.

Connect with clients

Whether in the production treatment or after sending out a sample, it’s reliable to connect with customers prompt. Clients along with clients will certainly have clear demands on the item specification and likewise feature when getting concerns from customers, we will definitely get in touch with them rapidly and also provide a completely free quote as soon as possible, if there is something not right, we’ll adjust the service quickly. For special requirements, please inform us ahead of time.