Rapid Prototyping & Rapid Manufacturing Expert

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion

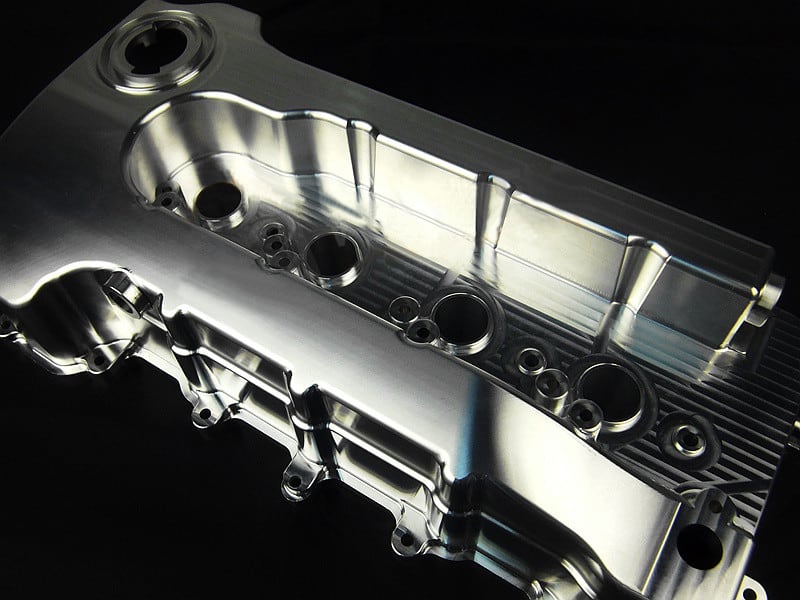

How to choose Aluminum 6061 or 7075 for CNC project?

Aluminum has excellent strength-to-weight ratio and corrosion resistance, and with excellent machinability compares to other metals such as steel and titanium. Aluminum widely used in automotive, sports equipment, electrical, construction and aerospace industries. Given the wide variety of Aluminum alloys available, choosing the right Aluminum alloy for your CNC machining project can be challenging. Especially for the two most commonly used grades Aluminum 6061 and 7075, it is important to understand the difference between these two alloys. T6 is the suffix for these two metals, and it indicates the treatment of the alloy to a specific state. This article compares these two Aluminum alloys from different perspectives such as composition, mechanical properties and cost to help you understand typical applications of aluminum 6061 vs 7075.

The main characteristics of Aluminum

Aluminum is a relatively soft, durable, lightweight and malleable metal that can vary in appearance from silver to dull grey, depending on surface roughness. It is non-magnetic with density 2.68g/cm3 , does not ignite easily, melts at 640 degrees and is very light. It is a good conductor of heat and electricity, but not as good as copper for wires of the same cross section. Aluminum really comes into play when it is combined with other metals to make an Aluminum alloy. Some common alloy elements include boron, copper, lithium, magnesium, manganese, silicon, tin, and zinc etc, Aluminum alloy parts manufactured by precision CNC machining are widely used in electronics, aerospace, medical and other industries.

Aluminum alloy with highly corrosion resistance, are sensitive to high temperatures above 200 °C to 250°C (392°F to 482°F), and may lose some strength. However, the strength of Aluminum alloys will increases somewhat at sub-zero temperature. This determines that Aluminum alloy is an ideal low temperature alloy.

Aluminum 6061

If you asking what the most common Aluminum alloy in the world? No doubt is Aluminum 6061. Aluminum 6061 alloy elements mainly include magnesium and silicon, has excellent mechanical properties and can be welded, after precipitation hardening treatment. Aluminum 6063 is also a popular choice, with smoother finish but about half the strength of Aluminum 6061, which because of the lower alloy elements proportion of magnesium and silicon. This makes Aluminum 6063 suitable for applications where strength does not matter.

High-toughness

Excellent surface finish

Excellent corrosion resistance when exposed to harsh conditions

Excellent corrosion resistance when exposed to seawater

Good anodizing effect

Excellent weldability

Excellent machinability

Aluminum 7075

The man alloy elements of Aluminum 7075 are zinc and copper, which is one of the strongest Aluminum alloys in the world. It has good performance in corrosion resistance, anodizing effect and machinability. Especially it has excellent mechanical properties, with high strength, toughness, good ductility and good fatigue resistance. Mainly use in aerospace and defense industries. While it is excellent in many ways, but the cost is quite expensive compared to other Aluminum alloys, which is why it is not used as much as Aluminum 6061. Use this alloy only when the basic properties of the alloy are required for a specific application. Otherwise, it may be better to use a cheaper Aluminum alloy. Aluminum 7075 is not recommended for welding.

High strength, comparable to steel

Highfatigue resistance

Moderate machinability

Best to use oil lubricants when CNC machining

Aluminum 6061 vs 7075 Difference

In this section, we will compare Aluminum 6061 and Aluminum 7075 according to several parameters.

Alloy element comparison. Aluminum 6061 is a member of the 6000 series, which are alloyed with silicon and magnesium as the main composition. Aluminum 7075 is a member of the 7000 series and use zinc, copper as the main alloying elements. The following table contains a comparison of the chemical composition of Aluminum 6061 and Aluminum 7075.

Chemical Elements | Aluminum 7075 | Aluminum 6061 |

% Aluminum (Al) | 90.0% | 97.9% |

% Magnesium (Mg) | 2.5% | 1.0% |

% Zinc (Zn) | 5.6% | — |

% Silicon (Si) | — | 0.6% |

% Chromium (Cr) | 0.23% | 0.2% |

% Cuprum (Cu) | 1.6% | 0.28% |

Aluminum 6061 vs 7075 Characteristic difference

Application

Machinability. Machinability refers to the ease degree of Aluminum alloys are cut (CNC machining), including milling, turning, cutting and casting. Aluminum 7075 has higher tensile stress and higher hardness than Aluminum 6061. Therefore, Aluminum 7075 is more difficult to process than Aluminum 6061.

Yield Strength. Aluminum 7075 has higher yield strength and can withstand greater stress and impact than Aluminum 6061. The yield strength of Aluminum 7075 depends on its chemical composition and heat treatment. However, Aluminum 6061 with yield strength of 276MPa is not weak.

Thermal Conductivity. Aluminum 6061 has higher thermal conductivity than Aluminum 7075. So if your CNC project is heat sink parts, Aluminum 6061 is your first option.

Resistivity. Aluminum 6061 and Aluminum 7075 are good electrical conductors, and are suitable for electrical purposes. But Aluminum 6061 has lower resistivity and is more suitable for manufacturing of conductive parts.

Elasticity. The elasticity of Aluminum 6061 and Aluminum 7075 is similar.

Temperature resistance. It is more appropriate to use the melting point to analyze the temperature resistance of Aluminum 6061 and Aluminum 7075. The melting point of Aluminum 6061 is 582°C – 652°C, while Aluminum 7075 is 477°C – 635°C. The former can withstand higher temperature.

Hardness. Aluminum 6061 and Aluminum 7075 are stiff enough to withstand pressure and not crack or deform. But Aluminum 7075 is harder than Aluminum 6061.

Corrosion resistance. Aluminum 6061 is more corrosion resistance than Aluminum 7075. As higher copper content of Aluminum 7075, and copper is a metal that readily produce chemical reaction with the environment.

Anodizing. The anodizing effect of Aluminum 6061 is significantly higher than Aluminum 7075.

How to select Aluminum 6061 VS 7075

Choosing between aluminum and steel can be very simple. But it will be tricky if answer the question“Which aluminum alloy is better for my CNC project”Both alloys have excellent mechanical properties and widely used. Then we need to consider priorities, such as the end use of the part. Of course, manufacturing conditions and cost are major consideration also.

The most important selling points of Aluminum 6061 are its low cost and versatility. It can be extruded and welded, with high machinability and good corrosion resistance. Its light weight and medium to high strength make it a popular choice for medical, electronics, automotive and applications.

The cost of Aluminum 7075 is higher than Aluminum 6061, as its stronger strength, better surface finish, only the machinability is slightly less. The most significant disadvantage of using the Aluminum 7075 is its lower corrosion resistance then Aluminum 6061.

Summary

Aluminum alloys are one of the most widely used metals. This article compares the differences between Aluminum 6061 and Aluminum 7075 based on various parameters, including their unique features and specific applications.

Therefore, you need to consider the properties of each material to ensure that the ideal material is selected for your CNC project. Do you felt it difficult to decide between Aluminum 6061 and Aluminum 7075? Then, you can contact with DDPrototype for ask support, DDPrototype with over 20 years CNC machining experience, and we are always ready for your CNC projects.

FAQ Aluminum 6061 and Aluminum 7075

For Aluminum 6061 and Aluminum 7075, which is easier to process?

Aluminum 6061 has lower tensile strength and hardness than Aluminum 7075. Therefore, Aluminum 6061 is easier to do machining than Aluminum 7075.

For Aluminum 6061 and Aluminum 7075, which is stronger?

Aluminum 7075 has higher yield strength than Aluminum 6061, as its chemical composition. Therefore, it can withstand impact better than Aluminum 6061 and is less deformed.

What should be considered when choosing between Aluminum 6061 and Aluminum 7075?

The intended application of the final product plays a crucial role in your selection of the more suitable material. In addition, the manufacturing process need be considered as the processing difficulty is different. Of course, cost is an important consideration also.